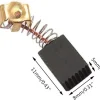

Carbon Motor Brush 10x5x5mm – Replacement Part for Electric Rotary Tools

Carbon Motor Brush 10x5x5mm – Replacement Part for Electric Rotary Tools

Ensure optimal performance for your electric rotary tools with this high-quality carbon motor brush. Measuring 10x5x5mm, it’s a vital motor carbon replacement component designed for smooth operation and durability, extending the life of your equipment. Perfect for routine rotary tool maintenance.

Original price was: $34.76.$17.38Current price is: $17.38.

With our Alive & Thrive Guarantee, we’ve got your back for the first 30 days! If you have any concerns about your plants, just reach out to us. Our team is here to help answer your questions and guide you in selecting the best plants for your garden, climate, and unique preferences. We're excited to help you create the garden of your dreams!

Estimated arrival

Jan 31

Feb 05 - Feb 07

Feb 10 - Feb 14

-

USDA Hardiness Zone

unknown -

Soil type

unknown -

Sunlight Exposure

not applicable -

Expected Planting Period

not applicable

Overview

This high-quality carbon motor brush is an essential replacement component for a wide range of electric rotary tools. Precisely engineered with dimensions of 10x5x5mm, this brush plays a critical role in the efficient operation of your motor, ensuring consistent power transfer and reduced wear on internal components. Whether you’re a professional tradesperson or a dedicated DIY enthusiast, maintaining your power tools with reliable parts is paramount. This electric rotary tool brush is designed to meet stringent performance standards, offering a cost-effective solution to common motor issues such and inconsistent power or complete tool failure. Investing in a quality 10x5x5mm carbon brush helps to prolong the lifespan of your valuable equipment and ensures that your tools are always ready for the next task.

Carbon brushes are consumable parts that conduct current between stationary wires and moving parts of a motor. Over time, these brushes wear down, leading to decreased motor efficiency or complete stoppage. Replacing them with a new carbon motor brush is a straightforward process that can restore your tool’s power and functionality. This specific 10x5x5mm size makes it suitable for various models, providing a versatile option for your toolkit. Proper rotary tool maintenance is crucial for safety and productivity, and having these replacement brushes on hand helps prevent unexpected downtime.

Key Benefits

Maintaining your electric rotary tools with a high-quality carbon motor brush offers several significant advantages, ensuring your equipment operates at its best and lasts longer.

- Restores Optimal Performance: A new carbon motor brush ensures efficient electrical contact, restoring your tool’s original power and speed for better work results.

- Extends Tool Lifespan: Regular replacement of worn brushes prevents damage to other motor components, significantly extending the overall life of your electric rotary tool.

- Reduces Downtime: Having spare brushes on hand allows for quick repairs, minimizing interruptions to your projects and ensuring continuous productivity.

- Cost-Effective Repair: Replacing a worn motor carbon replacement is much more economical than purchasing a new power tool, saving you money in the long run.

- Smooth Operation: Fresh carbon brushes contribute to smoother motor operation, reducing sparks and noise for a more pleasant and safer working environment.

- Easy Installation: Designed for straightforward replacement, allowing users to quickly swap out old brushes with new ones without needing specialized tools.

- Wide Compatibility: The standard 10x5x5mm carbon brush size makes it compatible with a broad range of electric rotary tools, offering versatility.

Tool Care & Usage Tips

Proper care and timely replacement of your carbon motor brush are crucial for maximizing the efficiency and longevity of your electric rotary tool. Always ensure your tool is unplugged before attempting any maintenance. Begin by locating the brush caps, typically found on the sides of the motor housing. Use a screwdriver to remove these caps carefully. Once the caps are off, gently pull out the old brushes. Observe the condition of the old brushes; if they are significantly shorter than new brushes or show signs of heavy wear, it’s time for a motor carbon replacement. Insert the new 10x5x5mm carbon brush into the housing, ensuring it slides in smoothly and makes proper contact with the commutator. Replace the brush caps securely.

After replacing the brushes, it’s recommended to run the tool at a low speed for a few minutes without a load. This allows the new brushes to seat properly against the commutator, ensuring optimal contact and reducing initial wear. Periodically inspect your brushes, especially if you use your tools frequently. Signs that your carbon brushes may need replacing include reduced power, intermittent operation, excessive sparking, or a burning smell. Proactive rotary tool maintenance, including regular brush checks, will prevent more serious damage to your motor and ensure your tool performs reliably for years to come. Remember, a well-maintained electric rotary tool brush is key to consistent and powerful performance.

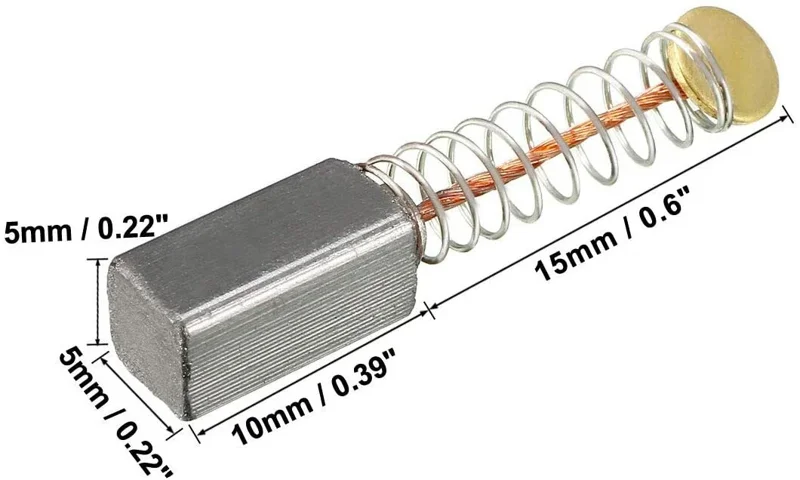

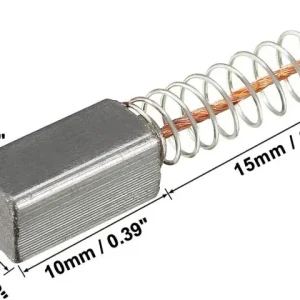

Size & Details

This essential carbon motor brush measures precisely 10x5x5mm, a standard size designed for compatibility with a variety of electric rotary tools. Each brush is crafted from high-quality carbon material, ensuring excellent conductivity and wear resistance for prolonged use. This product is typically sold as a pair, allowing for the complete replacement of both brushes in your motor, which is recommended for balanced wear and consistent performance. The compact size of these brushes ensures they fit snugly within the designated brush holders of compatible tools, facilitating easy installation and secure operation. Users can expect these brushes to provide reliable service, helping to maintain the efficiency and power output of their electric rotary equipment.

The brushes are designed to gradually wear down during use, which is a normal function of a motor carbon replacement. The lifespan of the brushes will depend on the intensity and frequency of tool usage. It’s always a good practice to keep a spare set of 10x5x5mm carbon brush replacements on hand for immediate repairs, minimizing downtime. This product is a crucial component for anyone performing regular rotary tool maintenance, ensuring their power tools remain in top working condition.

Frequently Asked Questions

- Q: How big is this carbon motor brush? A: This carbon motor brush measures 10x5x5mm, making it a suitable replacement for various electric rotary tools that require this specific size.

- Q: Is this brush compatible with all electric rotary tools? A: While it fits many models that use a 10x5x5mm carbon brush, it’s best to check your tool’s manual or existing brush dimensions to confirm compatibility for your specific electric rotary tool.

- Q: How often should I replace my carbon brushes? A: The frequency depends on tool usage. If you notice reduced power, excessive sparking, or your tool stops working, it’s likely time for a motor carbon replacement.

- Q: Is it difficult to replace a carbon motor brush? A: No, replacing a carbon motor brush is generally a simple process that can be done with basic tools, typically a screwdriver, by accessing the brush caps on your tool.

- Q: What are the benefits of timely carbon brush replacement? A: Timely replacement helps restore tool power, prevents damage to the motor, reduces sparking, and extends the overall lifespan of your electric rotary tool, making rotary tool maintenance more effective.

- Q: Will replacing the carbon brushes improve my tool’s performance? A: Yes, replacing worn-out brushes with a new electric rotary tool brush can significantly improve your tool’s power, efficiency, and overall performance, making it run smoother.

- Q: Do these brushes require any special break-in period? A: After installation, it’s advisable to run the tool without load for a few minutes at a low speed to allow the new carbon motor brush to seat properly against the commutator for optimal performance.